Bag Filters

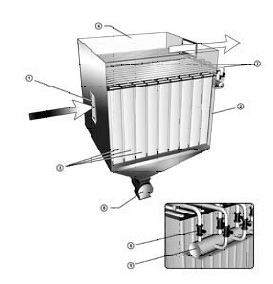

Bag filter with a pulse blow to the central systems Aspiration types of FDI

Bag filter with a pulse controller designed to clear the air of any fine dry noncoherent Dust.The filters have a built-in mechanism regeneration pulse scavenging air.Filter element is a sleeve on metal frames. Can be used in the production of a continuous cycle: woodworking, construction materials, foundries, fertilizer, etc. to capture fine dry noncoherent Dust.

Filters can be equipped with fan and air; cart-Dust Bags; locked-chamber transfer enabling continuous discharge of captured product bunkerom-drive with the sliding gate; cyclone-discharge to utilize a filter at concentrations up to 500g/m3. In the event of a return purified air into the room could complete control stage treatment.

How it works

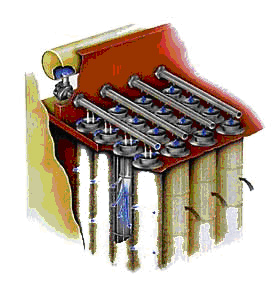

The principle of the bag filter is based on the capture dust filter cloth in passing through it dustiness air. As the thickness of the layer of dust on the surface of branches growing resistance movement of air and reduces the capacity of the filter to avoid making an regeneration dusty sleeves burst of compressed air. Dust-filled air enters the bag filter on the air through the tube into the chamber "dusty air" and passes through the sleeves, the particles of dust caught in their outer surface, and purified air enters the chamber "clean" air and has a filter.

By cell "dusty air" and compressed air receiver connected with the electromagnetic valves. The air from the receiver through the electromagnetic valve goes to purge the pipe. Regeneration dusty sleeves in the bag filter is implemented pulse of compressed air. The dust shaking off with sleeves, crumble into the bunker and after unloading device is removed from the filter.

Controlling of regeneration filter

A cleaning process is controlled automatically from the control panel.

To optimize the flow of compressed air at the following types of treatment:

As pressure drop- pulse blow activated when the differential pressure filter exceeds the value defined in the startup.

The continuous regeneration - pulse blasting performed regularly raised in intervals.

Use:

- Production of cement, lime and gypsum;

- Ferrous metallurgy, steel industry;

- Foundry;

- Non-ferrous metallurgy;

- Chambers combustion flue gas, dry sorption;

- Chemical and food industry;

- Timber industry, DSP production;

- Installations for the protection of the environment (ecology)

Specifications

- Productivity in the air, thousands nm3 / h: 1-1000;

- The hydraulic resistance, Pa: 400-3000;

- The effectiveness of cleaning dust,%: 99,0-99,99;

- Maximum concentration at the entrance to the filter, g/nm3: 1000;

- The concentration of dust at the exit from the filter, mg/nm3: 20-5;

- Maximum temperature of clean gas at the inlet, hail. Г‘: 400

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The flow of clean gas, nom.-max.

|

|

|

|

|

|

|

|

|

Nominal flow of compressed air

|

|

|

|

|

|

|

|

|

The maximum flow of electricity

|

|

|

|

|

|

|

|

|

The concentration of dust at the entrance, the largest

|

|

|

|

|

|

|

|

|

The concentration of dust at the outlet, the largest

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Limit discharge to the filter housing

|

|

|

|

|

|

|

|

|

Dimensions filter:

length;

width;

height.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|